Vertical Lifeline Assembly

What Is a Vertical Lifeline Assembly?

A vertical lifeline assembly (VLA) is something you would commonly find in your fall protection bucket kit. The VLA is made up of a high-strength poly-rope with self-locking snap hook and a rope grab positioning device for you to use as your connector.

https://youtu.be/l6PyBfip1lo

How Are VLAs Used?

Typical uses for a vertical lifeline assembly include roofing, ladder climbing, general construction, and tower climbing. You may use a VLA in fall arrest applications, stopping a worker who is already in the process of falling and bringing their body to a halt, but they are most used in fall restraint scenarios where the worker operates within a limited amount of space and the system stops them from reaching a dangerous fall hazard.

Components of a VLA

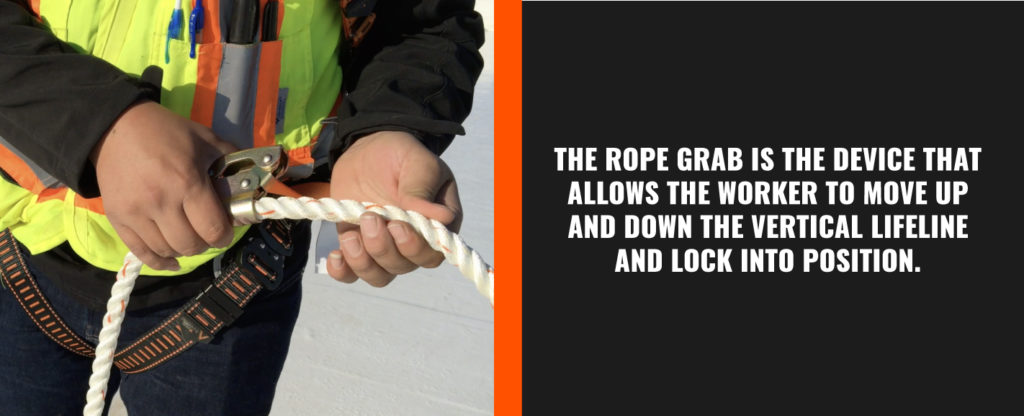

The Rope Grab

The rope grab is a crucial part of the VLA, acting as the connector between the worker’s full body harness and the poly-rope. It is manually operated, allowing the user to lock and unlock the device to move along the rope. Proper use of the rope grab is essential; once locked into place, it should not be touched during a fall to prevent unintentional disengagement.

The Shock Pack

A VLA typically includes a shock pack attached to the rope grab. This shock absorber device helps reduce the force exerted on the worker during a fall. Regular inspections are necessary to ensure the shock pack is intact and functional. Any signs of wear or damage indicate the need for replacement to maintain safety standards.

The Poly-Rope

The poly-rope is a high-strength synthetic fiber rope that forms the vertical lifeline. It is designed to withstand significant forces and provide a reliable connection between the worker and the anchor point. Key features include:

The Self-Locking Snap Hook

The self-locking snap hook is used to attach the poly-rope to an approved anchor point. This component ensures a secure and reliable connection, preventing accidental disengagement. Important characteristics include:

The Anchorage Connector

The anchorage connector is the point where the VLA is secured to the structure. It must be capable of supporting the loads imposed by a fall arrest system. Key considerations include:

How To Use a Vertical Lifeline Assembly

To use a vertical lifeline assembly, you must first use the self-locking snap hook to attach the poly-rope to an approved anchor point. Then, measure out the appropriate distance to allow the worker to move around safely in the work environment without reaching the edge or crashing into the ground if fall may occur. Make sure to factor in the length of the shock pack just in case the pack becomes deployed. Use the rope grab positioning device to solidify your location along the rope and lock it into place. Now you are safe to move around the workspace and avoid the fall hazards.

VLA Limitations and Precautions

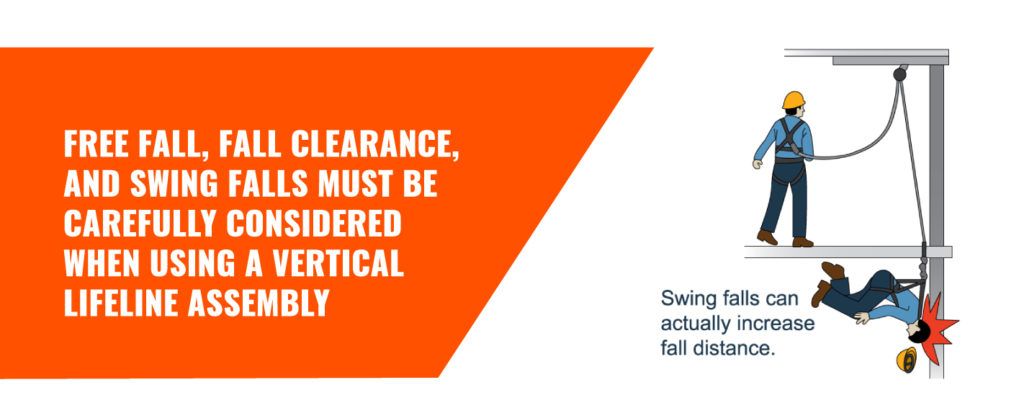

When you use any fall protection equipment, you must consider the limitations of the devices you are trusting your life to before you get to work. Free fall, fall clearance, and swing falls are all important factors to be aware of.

Free Fall: According to ANSI Z359.1, when using a VLA in conjunction with a personal fall arrest system, the free fall distance must be limited to 6’. When you use the vertical lifeline assembly in fall restraint, the requirement is that no fall will be encountered so there is absolutely no free fall distance allowed.

Fall Clearance: It is incredibly important that fall clearance is calculated properly. When using the vertical lifeline system in fall arrest scenarios, there must be enough room below the worker to successfully arrest the fall before they hit the ground or lower surface. A competent person should perform a hazard assessment to calculate the fall clearance before any work at heights is started.

Swing Falls: One of the most lethal and overlooked hazards in fall protection. A swing fall happened when the anchorage point is not directly above the worker and is instead off to the side. This creates an angle that can mislead fall clearance calculations and cause the worker to impact the ground or another structure if a call occurs. Swing falls will significantly increase the clearance required to arrest a fall.

OSHA and ANSI VLA Standards

OSHA has strict guidelines to keep in mind when using a vertical lifeline assembly. Here are a few to be aware of that directly correlate to VLA’s and their use in the workplace.

According to OSHA 1910.140(c)(3), “when vertical lifelines are used, each employee must be attached to a separate lifeline.” This differs from a horizontal lifeline assembly where you can have multiple workers tied off to one system.

As is the standard for many fall protection precautions, anchors, and lifelines; per OSHA 1910.140(c)(4); “lanyards and vertical lifelines must have a minimum breaking strength of 5,000 pounds (22.2 kN).”

DO NOT tie knots in rope lifelines. Knots in rope significantly reduce the rope’s strength and integrity. The only knots that are permitted are limiter knots at the end of the system to limit the distance of that the rope grab can travel. As stated in OSHA 1910.140(c)(6); “a competent person or qualified person must inspect each knot in a lanyard or vertical lifeline to ensure that it meets the requirements of paragraphs (c)(4) and (5) of this section before any employee uses the lanyard or lifeline.”

Malta Dynamics uses a high strength poly-rope to ensure our products exceed the OSHA standard1910.140(c)(15) which mandates that “lifelines must not be made of natural fiber rope. Polypropylene rope must contain an ultraviolet (UV) light inhibitor.”

These standards, among many other safety requirements will help you to make sure you are using your fall protection equipment safely and correctly. Do not overlook the importance of reading the manuals and following the proper protocols, your life is precious.

Key regulations include:

OSHA 1910.140(c)(3): Each employee must be attached to a separate vertical lifeline.

OSHA 1910.140(c)(4): Lanyards and vertical lifelines must have a minimum breaking strength of 5,000 pounds.

OSHA 1910.140(c)(6): Knots in rope lifelines are prohibited except for limiter knots inspected by a competent person.

OSHA 1910.140(c)(15): Lifelines must be made of high-strength synthetic fibers and include UV light inhibitors.

Have a fall protection question?

Submit your question, and you could be featured on Dynamic Discussions!