5 Preferred methods of working at height

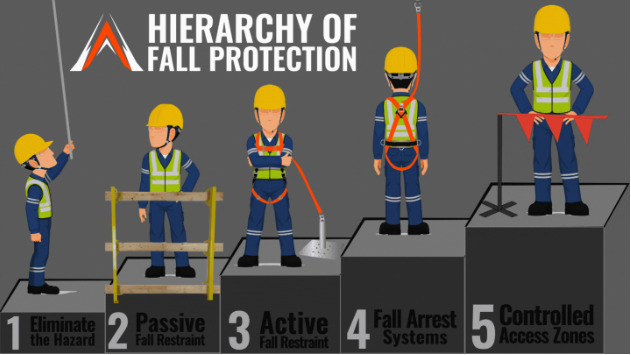

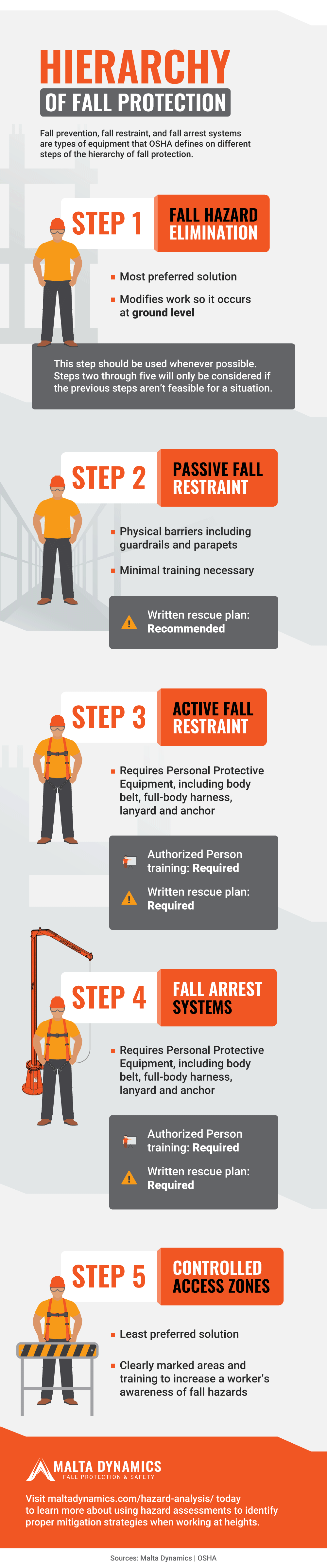

Fall protection is a critical aspect of workplace safety. With falls being the leading cause of fatalities in the construction industry according to The Occupational Safety and Health Administration (OSHA), it is essential to implement fall protection measures to prevent injuries and fatalities. In this article, we will discuss the 5 preferred methods of fall protection. This is a guide to ensuring your workers are as safe as possible for the required task. The succession begins with removing fall hazards, then passive fall restraint, active fall restraint, fall arrest, and finally controlled access zones. This is what Malta Dynamics calls the Hierarchy of Fall Protection

1. REMOVING FALL HAZARDS

At the top of the hierarchy of fall protection lies hazard elimination. Removing fall hazards altogether is the best solution to ensure safety. This can be achieved by performing work on ground level and then using material handling equipment to place materials at heights, engineering controls to be used at ground level, or using materials at heights that require zero maintenance and inspection, if possible. This method emphasizes the principle that the safest way to work at height is not to work at height at all.

2. PASSIVE FALL RESTRAINT

Moving a step down the fall protection hierarchy, passive fall restraint is an optimal method when hazard elimination isn’t possible. Guardrails, safety nets, and other physical barriers not only provide protection against potential hazards but also grant workers the freedom of movement. The advantage of passive systems like these is that they don’t rely on the worker to use them correctly. Because there is no risk of a fall, the worker does not wear a safety harness, nor are they required to receive and maintain specific fall arrest training for that hazard area.

These methods are the preferred solution for many safety professionals because they work without the active participation of the worker. This reduces the chances of human error, which is often a significant cause of accidents in a work area. Passive fall restraint is especially preferred in factories or facilities that are permanent or semi-permanent, and on work that is performed regularly.

3. ACTIVE FALL RESTRAINT

Active fall restraint systems limit the worker’s movement, preventing them from reaching the fall hazard. Using equipment like full-body harnesses, and lanyards, and connecting to an anchor point, workers can safely move within a designated access zone. The application of these methods requires proper training to ensure that each worker is well-versed in the nuances of the equipment. This also ensures a minimum requirement for clearance margins, so there is ample fall distance before the worker encounters any lower-level obstacles or surfaces. Active fall restraint systems are ideal for areas where the fall hazard cannot be removed or protected with passive fall restraint systems.

4. FALL ARREST

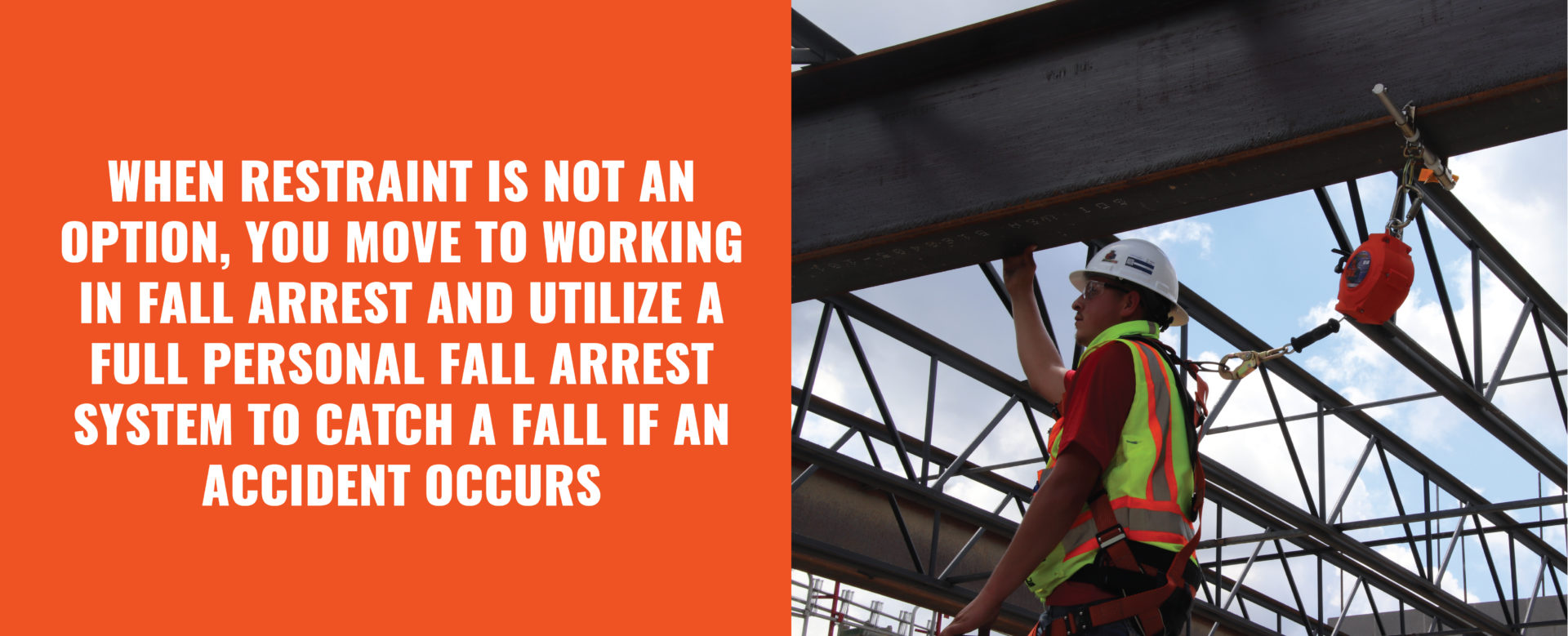

In a construction site’s unpredictable environment, the fall arrest system is vital for those scenarios where fall hazards can’t be completely removed. Utilizing a self-retracting lifeline or other fall arrest systems means that, even if a fall occurs, the equipment will minimize swing-fall, freefall distance, and arresting forces to the body of the worker. A personal fall arrest system (PFAS) includes anchorage, bodywear (full body harness), connector (properly rated carabiners and attachment points), and a deceleration device (lanyard or self-retracting lifeline (SRL).

When a worker falls, the PFAS activates, arresting their fall and preventing them from hitting a lower level or other objects that can cause injury. A competent person within the team should always inspect the fall arrest equipment, ensuring it is in optimal condition. Fall protection equipment needs to be regularly checked and maintained, ensuring the safety of every worker. Fall arrest systems are ideal for areas where the fall hazard cannot be removed or protected with passive or active fall restraint systems.

5. CONTROLLED ACCESS ZONES/SAFETY MONITORING SYSTEMS

The last layer of the fall protection hierarchy emphasizes the importance of administrative controls. Controlled access zones are areas where visual barriers represent a no-go area, preventing workers from accessing the fall hazard. Establishing controlled access zones ensures that only those with proper training and equipment enter hazardous areas. These zones are often used in conjunction with other fall protection systems such as passive fall restraint and active fall restraint. Controlled access zones are ideal for areas where the fall hazard cannot be removed or protected with other fall protection systems.

Safety monitoring systems are an option on low-slope roofs that incorporate a Competent Person who monitors the hazard area and acts as an attendant for the zone. It’s important to note that the controlled access zone and safety monitor options are a last resort. OSHA is specific in mentioning that they are options only if the more safe options are proven unfeasible, however, OSHA assumes that the other options would be feasible, so if you’re incorporating one of these last 2, it’s a good idea to document that you’ve exhausted the safer options.

FALL PROTECTION EQUIPMENT & TRAINING – AN INTEGRAL COMPONENT

Possessing a firm grasp of the hierarchy of fall protection and being equipped with top-tier tools is crucial. However, the real effectiveness of these resources relies on their effective implementation. Here’s how industries, safety professionals, and workers can bridge the gap between understanding and execution.

Site Assessment:

Before diving into work, it’s essential to conduct a thorough site assessment. This involves identifying all potential fall hazards, gauging the height at which tasks will be performed, and ensuring that there are no obstructions in the potential fall zone. By understanding the landscape, appropriate fall protection methods can be selected and deployed.

Continuous Training:

Fall protection isn’t a one-time lesson. As new equipment is introduced and as standards evolve, proper training becomes paramount. This might include height training, understanding the nuances of newly introduced gear, or even simulated fall scenarios to help workers understand how systems work in real-world conditions.

Safety Checks:

Every piece of equipment, whether it’s a harness, an anchor point, or a self-retracting lifeline, should be inspected before each use. A quick but thorough check can identify wear and tear, ensuring that no faulty equipment is in use. For more intensive checks, consider a safety stand-down.

Staying Updated:

In the realm of occupational safety, changes can stem from technological advancements, new research findings, or regulatory updates. Staying up to date on these changes ensures that your safety measures are always a step ahead of potential hazards.

Encourage a Culture of Safety:

Finally, and perhaps most importantly, fostering a workplace culture where safety is valued ensures that every individual feels responsible. When every person on your construction site becomes a safety monitor, the group’s vigilance drastically reduces the chances of oversights and accidents.

In conclusion, fall protection is essential for workplace safety, and employers must take proactive measures to protect workers from falls. By removing fall hazards, implementing passive and active fall restraint systems, using fall arrest systems, and creating controlled access zones, employers can prevent injuries and fatalities. Fall protection isn’t just about equipment; it’s about fostering an environment where safety is paramount.

See what OSHA says about this here: https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.502

Have a fall protection question?

Submit your question, and you could be featured on Dynamic Discussions!