How Are VLAs Used?

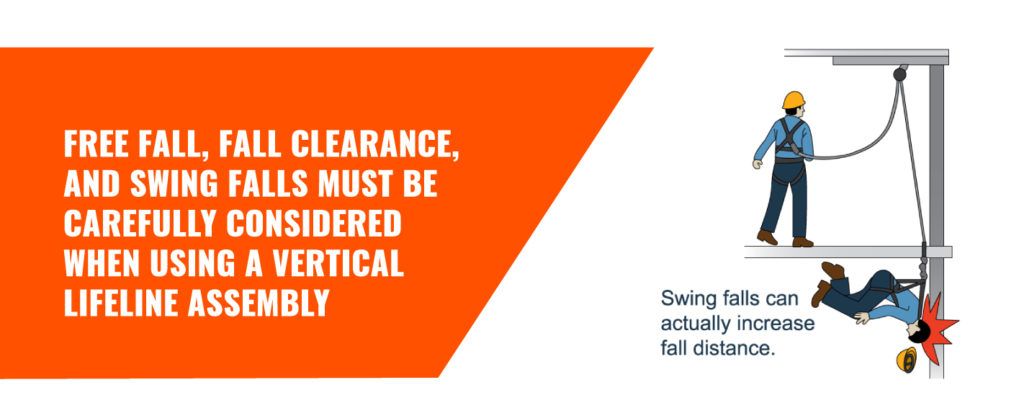

Typical uses for a vertical lifeline assembly include roofing, ladder climbing, general construction, and tower climbing. You may use a VLA in fall arrest applications, stopping a worker who is already in the process of falling and bringing their body to a halt, but they are most used in fall restraint scenarios where the worker operates within a limited amount of space and the system stops them from reaching a dangerous fall hazard.

OSHA and ANSI VLA Standards

OSHA has strict guidelines to keep in mind when using a vertical lifeline assembly. Here are a few to be aware of that directly correlate to VLA’s and their use in the workplace.

According to OSHA 1910.140(c)(3), “when vertical lifelines are used, each employee must be attached to a separate lifeline.” This differs from a horizontal lifeline assembly where you can have multiple workers tied off to one system.

As is the standard for many fall protection precautions, anchors, and lifelines; per OSHA 1910.140(c)(4); “lanyards and vertical lifelines must have a minimum breaking strength of 5,000 pounds (22.2 kN).”

DO NOT tie knots in rope lifelines. Knots in rope significantly reduce the rope’s strength and integrity. The only knots that are permitted are limiter knots at the end of the system to limit the distance of that the rope grab can travel. As stated in OSHA 1910.140(c)(6); “a competent person or qualified person must inspect each knot in a lanyard or vertical lifeline to ensure that it meets the requirements of paragraphs (c)(4) and (5) of this section before any employee uses the lanyard or lifeline.”

Malta Dynamics uses a high strength poly-rope to ensure our products exceed the OSHA standard1910.140(c)(15) which mandates that “lifelines must not be made of natural fiber rope. Polypropylene rope must contain an ultraviolet (UV) light inhibitor.”

These standards, among many other safety requirements will help you to make sure you are using your fall protection equipment safely and correctly. Do not overlook the importance of reading the manuals and following the proper protocols, your life is precious.

Key regulations include:

OSHA 1910.140(c)(3): Each employee must be attached to a separate vertical lifeline.

OSHA 1910.140(c)(4): Lanyards and vertical lifelines must have a minimum breaking strength of 5,000 pounds.

OSHA 1910.140(c)(6): Knots in rope lifelines are prohibited except for limiter knots inspected by a competent person.

OSHA 1910.140(c)(15): Lifelines must be made of high-strength synthetic fibers and include UV light inhibitors.