Understanding OSHA Fall Protection Standards

Falls are among the most common causes of serious work-related injuries and fatalities, and fall protection consistently ranks as OSHA’s most frequently cited safety violation. The Occupational Safety and Health Administration (OSHA) has established fall protection standards to reduce these risks, safeguard workers, and ensure a safer workplace. This blog will provide you with insight and resources to ensure you are meeting all necessary standards.

What are the OSHA Standards?

OSHA has established specific regulations under two primary sections to address fall protection across various industries. These standards are designed to minimize the risk of workplace injuries and fatalities while ensuring employers take proactive steps to safeguard their workers.

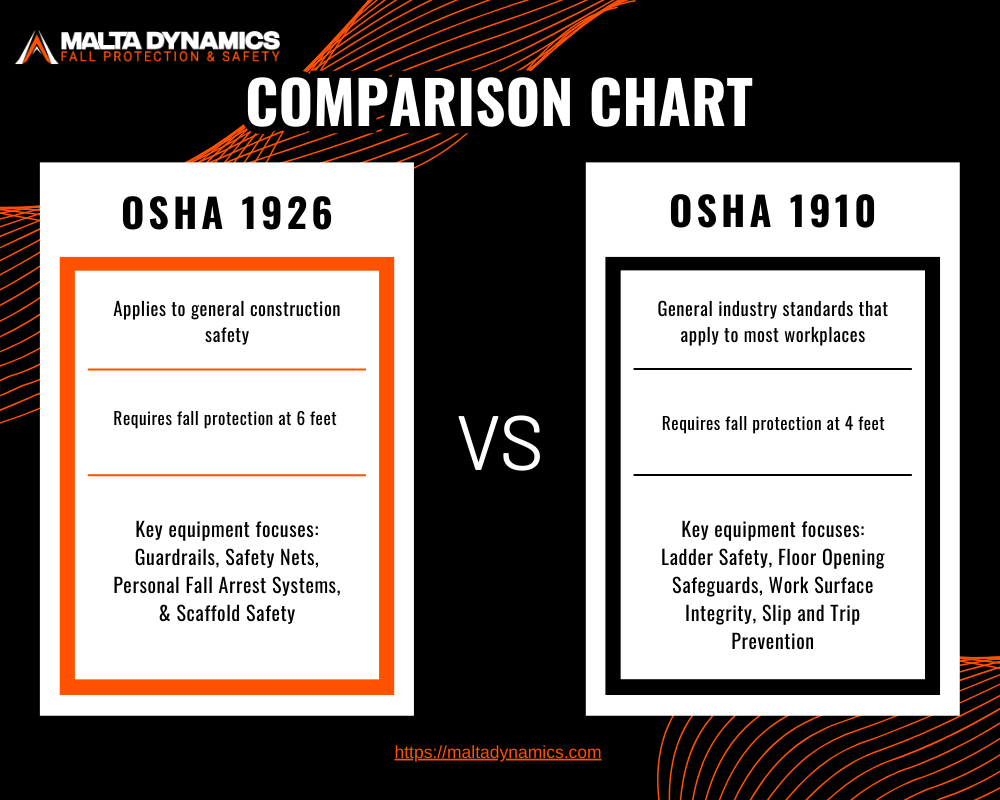

OSHA 1926: Construction Industry Standards

The OSHA 1926 standards apply to construction sites where workers face significant fall hazards due to the nature of their tasks and are operating at heights of 6 feet or more. Key requirements under these standards include:

- Guardrails: Guardrail systems must be installed around elevated work surfaces, such as platforms and rooftops, to prevent falls.

- Safety Nets: Safety nets should be deployed in areas where guardrails or personal fall arrest systems are impractical, providing an additional layer of protection.

- Personal Fall Arrest Systems (PFAS): Workers must use PFAS, including harnesses and lanyards, that meet OSHA’s stringent load-bearing requirements.

- Scaffold Safety: Regulations require that scaffolding be properly constructed, secured, and inspected to ensure stability and worker safety.

OSHA 1910: General Industry Standards

The OSHA 1910 standards address fall protection in general workplaces such as factories, warehouses, and retail stores where protection is required at heights of 4 feet or more. These standards focus on:

- Ladder Safety Standards: Employers must ensure ladders are properly maintained, securely placed, and used only within their weight and height limits to avoid an accidental fall.

- Floor Opening Safeguards: Floor openings and holes must be covered or guarded to prevent accidental falls.

- Work Surface Integrity: Elevated work surfaces must be sturdy and capable of supporting the intended load to reduce the risk of collapse.

- Slip and Trip Prevention: Employers must implement measures to prevent slippery or cluttered surfaces that could lead to falls.

Regardless of height, fall protection is necessary in situations where there is a risk of falling into or onto dangerous machinery or equipment, such as conveyor belts, tanks, or industrial machines.

By adhering to these standards, employers can not only protect their workforce but also avoid costly OSHA fines and legal liabilities. Both sections emphasize the importance of planning, equipping, and training workers to effectively manage fall hazards in diverse work environments

Training and Certification Requirements

OSHA requires initial training and retraining whenever new equipment is introduced or if safety protocols change, ensuring that employees stay updated on best practices and regulations.

All employees exposed to fall hazards, including those who use fall protection systems like harnesses and lanyards, must receive comprehensive training.

Training should thoroughly cover the proper use of equipment, such as harnesses and lanyards, while ensuring employees can recognize potential hazards in their work environment. It should also include an in-depth review of the company’s fall protection plan, outlining protocols and emergency procedures to ensure that all workers understand their roles in maintaining safety on the job site. Malta Dynamics can conduct and coordinate your safety training, see our on-site and virtual options.

What Are The Common OSHA Violations?

On the other hand, common OSHA violations reveal areas where workplaces frequently fall short. These include the failure to provide adequate fall protection systems, leaving workers vulnerable to preventable accidents. Many employers also neglect to conduct regular equipment inspections, allowing damaged or worn-out gear to remain in use, thereby increasing the risk of failure.

Additionally, insufficient training on fall hazards and prevention contributes to unsafe practices, as workers may not fully understand how to use protective equipment or recognize potential dangers in their environments. Addressing these hazards and avoiding these violations requires a proactive approach, including thorough hazard assessments, consistent training programs, and strict adherence to OSHA’s regulations.

What Are Some Common Hazards To Look Out For?

Some of the most common hazards include slippery surfaces, which significantly increase the likelihood of accidental falls, particularly in areas prone to spills or weather exposure.

Improper use of ladders, whether due to incorrect setup or overloading, remains a leading cause of workplace injuries.

Unprotected edges and floor holes are especially prevalent in construction and industrial sites, creating dangerous fall risks for workers who are not adequately safeguarded by barriers or covers.

How to Prepare for an OSHA Inspection

OSHA inspectors evaluate several critical aspects during an inspection to ensure compliance with fall protection standards. This includes the proper implementation of fall protection mechanisms, such as guardrails, safety net systems, and personal fall arrest systems, across all work areas. Inspectors also review up-to-date training records and certifications to verify that workers and competent persons have received adequate education on identifying and mitigating fall hazards. Additionally, they examine equipment maintenance and inspection logs to confirm that all gear, including harnesses, lanyards, and anchorage points are properly maintained and free from damage.

Tips for Compliance:

- Conduct Mock Inspections: Regular internal audits can help identify potential compliance issues before an OSHA visit. These audits should simulate real inspections and focus on assessing fall protection systems, training programs, and equipment maintenance.

- Develop a Fall Protection Plan: A comprehensive fall protection plan is essential for ensuring safety and compliance. This document should outline hazard assessments, safety protocols, and emergency response procedures. Ensure the plan is updated regularly and accessible to all employees.

- Keep Records Organized: Maintain thorough and well-organized documentation, including training logs, equipment inspection records, and incident reports. Having these records readily available demonstrates your commitment to compliance and safety.

- Engage a Competent Person: Designate a competent person to oversee fall protection requirements on-site. Their expertise can help identify hazards and implement corrective measures effectively.A Competent Person is generally a trained safety professional who coordinates safety efforts for a company. There can be more than one per company or site, and it is the responsibility of the company/employer to designate the Competent Person.

How Malta Dynamics Ensures Fall Protection Compliance

Malta Dynamics provides industry-leading solutions to help employers meet OSHA fall protection standards with ease. Their offerings include high-quality personal protective equipment that meets or exceeds OSHA standards, ensuring both reliability and safety on the job. In addition to equipment, Malta Dynamics delivers comprehensive training programs tailored to the specific needs of each team, helping workers become well-prepared and certified in fall protection best practices. The company also offers expert guidance to assist employers in creating effective fall protection plans and navigating complex OSHA requirements through fall protection inspections, making them a trusted partner in workplace safety.

OSHA’s fall prevention standards are not just requirements—they are critical for creating a safe and secure work environment that protects lives and enhances productivity. By taking proactive steps such as thorough training, using reliable equipment, and conducting regular safety assessments, employers can drastically reduce workplace injuries and fatalities while fostering a culture of safety. Partnering with a trusted expert like Malta Dynamics ensures that your team can avoid the worst-case scenarios and is equipped with the tools and knowledge to meet these standards with confidence.

Maintain OSHA compliance and prioritize safety by contacting Malta Dynamics today and exploring our fall protection solutions!