Extension Ladder Safety: A Guide to Preventing Injuries on the Job

If you’re working on a construction site, in masonry, or in any industry requiring elevation, chances are you’ve used an extension ladder before. While it may seem like a straightforward tool, ladder safety isn’t something to take lightly. Every year, thousands of workers suffer from ladder injuries, many of which could have been avoided with the right precautions.

The majority of these accidents occur due to improper setup, choosing the wrong ladder type, or failing to check for visible defects before use. Understanding proper ladder safety training doesn’t just protect you; it keeps your coworkers safe, prevents costly downtime, and ensures compliance with occupational safety regulations.

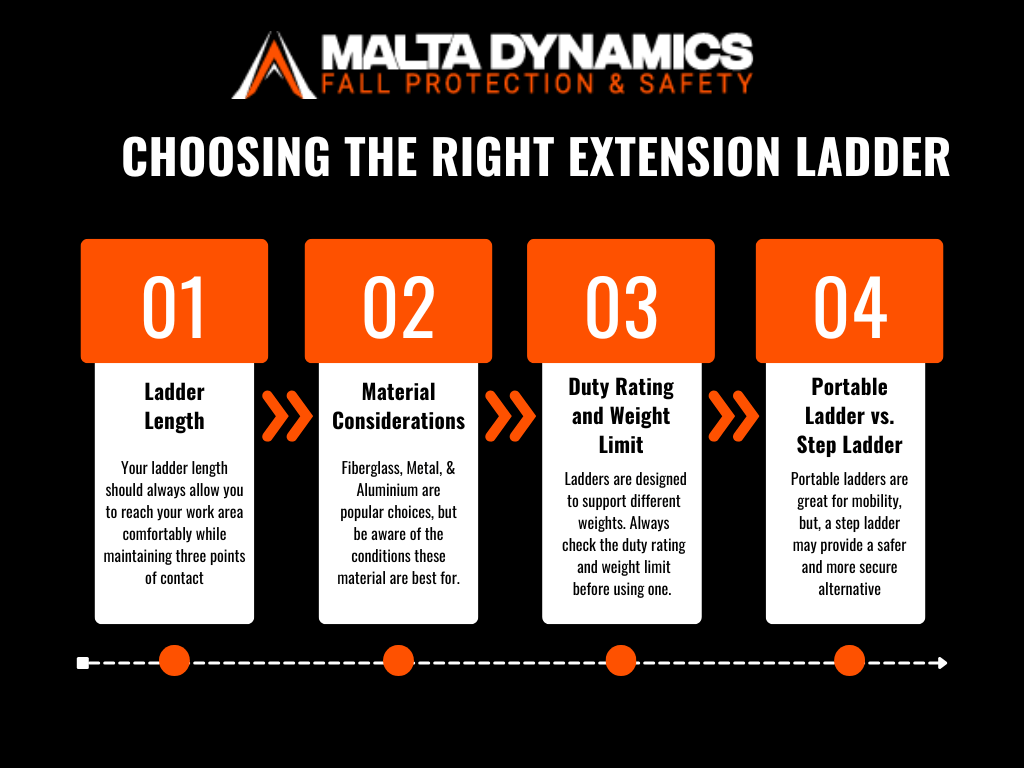

Choosing the Right Extension Ladder

Not all ladders are built the same, and using the wrong one can put you at unnecessary risk. Before you climb, consider a few key factors:

- Ladder Length: A common mistake is using a ladder that’s too short for the job. Your ladder length should always allow you to reach your work area comfortably while maintaining three points of contact. Never stand on the top section or overreach beyond the ladder’s horizontal position.

- Material Considerations: Understanding which ladder materials are best suited for your job site is a crucial part of safety. Aluminum ladders are lightweight and durable, but they should never be used near electrical equipment or power lines due to conductivity. In these cases, opt for a fiberglass ladder instead. Steel ladders are another popular choice, but they require extra caution in high-voltage environments.

- Duty Rating and Weight Limit: Ladders are designed to support different weights. Always check the duty rating and weight limit before using one. Overloading a ladder, especially with heavy tools or materials, increases the risk of structural failure.

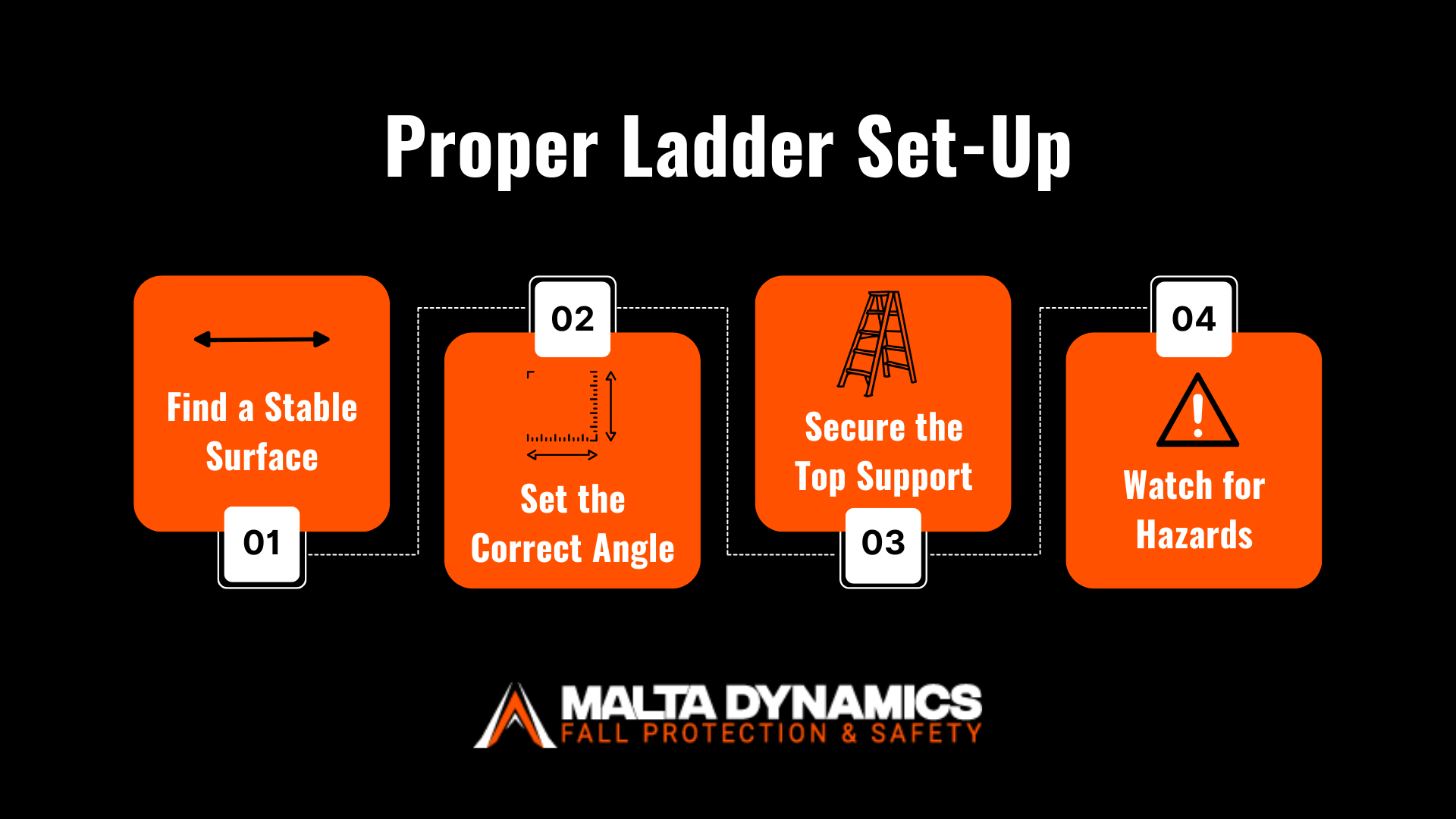

Proper Setup: Avoiding Common Mistakes

Most ladder injuries occur due to mistakes or oversight before a worker even starts climbing. Setting up an extension ladder correctly is crucial for stability and safety.

1. Find a Stable Surface

The ladder base should always rest on firm, level ground. Avoid slippery surfaces like wet concrete, loose gravel, or ice. If you are working on unstable bases, use ladder stabilizers or leveling devices.

2. Set the Correct Angle

A ladder that’s too steep can tip backward, while one that’s too shallow may slide out from under you. Follow the 4:1 rule. For every four feet of height, place the bottom section of the ladder one foot away from the wall. This ensures the correct angle for safe climbing.

3. Secure the Top Support

Before climbing, make sure the top support of the ladder is anchored. If you’re working on a construction site, tie off the ladder to prevent shifting. Unsecured ladders are a leading cause of fall injuries and serious accidents.

4. Watch for Hazards

Always scan your work area for potential dangers. Overhead power lines are an immediate hazard; make sure your ladder is at least 10 feet away from any electrical source. High winds can also destabilize a ladder, making climbing unsafe. If conditions are poor, postpone ladder work.

Safe Climbing and Usage Techniques

Even with the perfect setup, how you use a ladder matters just as much. Following safe climbing techniques can drastically reduce the risk of ladder injuries.

- Three Points of Contact: Always maintain three points of contact while climbing. Two hands and one foot or two feet and one hand. This keeps you stable even if the ladder shifts slightly.

- Use a Tool Belt: Carrying tools in your hands while climbing is a recipe for disaster. Use a tool belt or a pulley system to transport equipment safely.

- Face the Ladder: Never turn your body away while climbing or descending. Always face the rungs and move slowly.

- Avoid Overreaching: If you can’t reach your work area comfortably, reposition the ladder instead of leaning too far to the side. This prevents loss of balance and potential falls.

Preventing Ladder Injuries and Ensuring OSHA Compliance

Ladder safety training is about more than just preventing falls, it’s essential for maintaining compliance with OSHA 29 CFR 1926.1053 and creating a safer workplace.OSHA requires that ladders be inspected before each use by a competent person, someone trained to recognize potential hazards like cracks, bent side rails, or worn safety feet.

The goal of this training isn’t just to check a box, it’s to develop workers into competent persons who can confidently inspect ladders, identify risks, and enforce safety protocols. Without proper training, workers may unknowingly use damaged or improperly positioned ladders, increasing the risk of falls and serious injuries.

Regular safety meetings should reinforce ladder inspection procedures, weight capacity limits, proper climbing techniques, and fall protection measures. Training should also cover best practices for securing ladders on unstable surfaces and recognizing common hazards, such as overhead electrical lines or improper ladder placement.

The Role of a Competent Person in Ladder Safety

A competent person plays a critical role in workplace safety, ensuring that ladders are properly inspected and used according to OSHA regulations. Their responsibilities include:

- Conducting thorough ladder inspections before each use to identify damage or wear

- Enforcing safe ladder use policies and best practices

- Providing workers with the training needed to become competent persons

- Overseeing the correct use of fall protection equipment when required

Understanding Fall Protection Requirements

For tasks performed at heights, OSHA requires fall protection systems, including personal fall arrest systems, guardrails, or positioning devices. Workers must be trained to:

- Select and inspect harnesses, lanyards, and anchor points

- Understand fall arrest procedures and how to prevent falls

- Recognize when and where fall protection is required under OSHA standards

Employers are responsible for providing high-quality fall protection and ensuring that workers know how to use it effectively. Routine inspections of this equipment are just as important as ladder inspections to maintain a safe work environment.

Creating a Culture of Safety

Ladder safety isn’t just about meeting regulations, it’s about protecting workers and preventing avoidable injuries. A strong safety culture starts with leadership and is reinforced through proper training, oversight, and a commitment to OSHA compliance. If your workplace doesn’t already have a structured ladder safety program, now is the time to implement one. Training workers to become competent persons helps reduce risks, improve compliance, and create a safer job site for everyone.

How Malta Dynamics Can Help

At Malta Dynamics, we understand the risks workers face when using extension ladders. That’s why we offer industry-leading fall protection solutions designed to keep you safe at any height. Our products and training programs help ensure compliance, minimize risk, and give workers the confidence they need to do their jobs safely.

From high-quality fall protection equipment, comprehensive ladder safety training in our training programs to fall protection inspections to ensure your equipment is compliant, Malta Dynamics provides the tools and knowledge necessary for safe operations. Protect yourself, your team, and your job site with safety solutions trusted by industry professionals.