Are Ladder Cages Still Required?

Ladder cages used to be the go-to for fall protection on fixed ladders. But with OSHA’s updated rules, that’s no longer the case. If you have a fall arrest system or a ladder safety system, you don’t need a ladder cage. In fact, OSHA has been phasing out ladder cages in favor of better fall protection methods.

So, what does that mean for your job site? If you’re using a fixed ladder that’s over 24 feet, it must have either a fall arrest system or a ladder safety system—not just a ladder cage.

This shift is all about safety. Ladder cages might help guide a fall, but they don’t stop one. That’s why OSHA now focuses on fall arrest systems that actually stop a worker from falling instead of just containing them inside the ladder section.

Understanding OSHA’s Revised Ruling on Ladder Safety

OSHA’s ladder safety rules have changed, and if you’re working with fixed ladders over 24 feet, it’s important to know what that means for you.

What Changed?

Before 2017, OSHA required caged ladders as a fall protection measure for fixed ladders over 24 feet. The idea was that the cage would keep a climber contained and reduce the risk of a serious fall. However, ladder cages don’t actually stop falls.

To improve worker safety, OSHA updated Subpart D to require more effective fall protection. Now, any new fixed ladder over 24 feet must have either:

- A ladder safety system – This includes vertical lifelines, cable systems, or rail systems that allow climbers to stay securely attached as they move up and down the ladder.

- A personal fall arrest system (PFAS) – A harness and lanyard connected to a secure anchor point, designed to stop a fall in progress.

Why the Change?

- Higher Risk of Injury – Workers who fall inside caged ladders can still hit the rungs, cage bars, or a lower level, leading to severe injuries.

- Better Technology Available – Ladder safety systems and personal fall arrest systems provide continuous protection from the moment a worker starts climbing.

- Stronger Industry Safety Standards – Many industries, like construction and general industry, were already shifting toward active fall protection instead of relying on cages alone.

What’s the Deadline?

If a new fixed ladder is installed today, it must have a ladder safety system or fall arrest system—no ladder cages allowed.

If you’re using an existing fixed ladder with a cage, you have until November 18, 2036, to upgrade it.

What About Portable Ladders?

These rules only apply to fixed ladders over 24 feet. If you’re using a portable ladder, OSHA’s fall protection rules still apply, but there’s no requirement for a ladder safety system or fall arrest system.

So, if you’re still relying on a caged ladder, now’s the time to start planning for an upgrade.

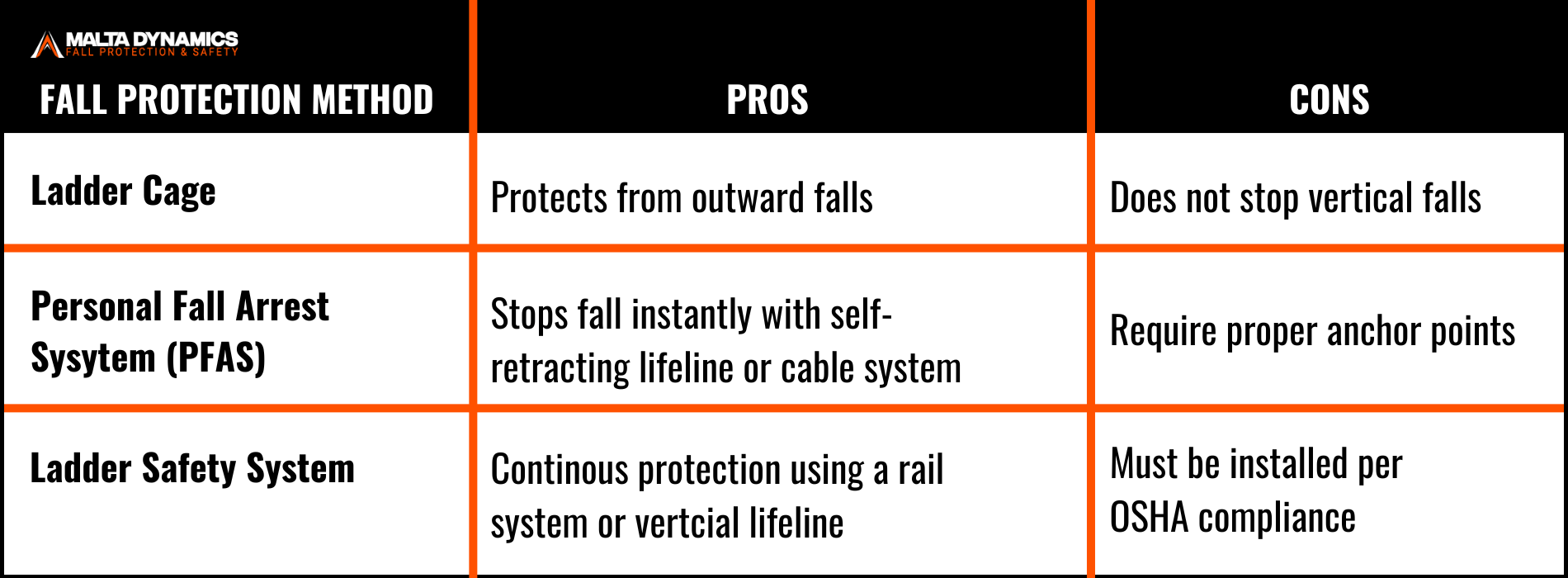

Ladder Cages vs. Modern Fall Protection Systems

When it comes to keeping workers safe on fixed ladders, understanding the differences between traditional ladder cages and modern fall protection systems is crucial.

Why Ladder Cages Are Being Phased Out

Ladder cages have been a common sight on many job sites. They were designed to encase the climber, aiming to prevent falls. However, real-world experiences have shown that while cages might guide a falling worker, they don’t actually stop the fall. This can lead to serious injuries, as the individual can still descend rapidly within the cage, potentially hitting the ground or other structures, and with falls being the leading cause of workplace injuries, OSHA now requires better protection like fall arrest systems that catch a worker mid-fall.

Recognizing this limitation, OSHA updated its standards. The new rules emphasize the use of systems that actively arrest falls, providing a more reliable safety net for workers.

Benefits of Upgrading

Transitioning from caged ladders to modern fall protection systems offers several advantages:

- Enhanced Safety: Modern systems are designed to prevent falls, not just contain them.

- Compliance with OSHA Standards: Meeting the latest regulations helps avoid potential fines and ensures a safer workplace.

- Improved Rescue Operations: In case of an incident, modern systems simplify rescue efforts, reducing risks to both the fallen worker and the rescuer.

By understanding these differences and the benefits of modern systems, employers can make informed decisions that prioritize worker safety and align with current regulations.

What Employers Need to Do for OSHA Compliance

If you’re in charge of job site safety, it’s important to know what steps to take to follow OSHA’s new ladder safety rules. Whether you’re working with existing fixed ladders or installing new ones, here’s what you need to do to stay compliant.

1. Inspect Your Ladders (Preliminary Investigation)

Start by reviewing all fixed ladders over 24 feet on your site. If they have ladder cages but no ladder safety system or fall arrest system, you’ll need to upgrade before the deadline.

Key things to check:

- Does the ladder have a ladder safety device, personal fall arrest system, or vertical lifeline?

- Is the ladder system installed properly and anchored to a secure point?

- Are workers using a self-retracting lifeline or cable system where required?

- Are there grab bars and landing platforms in place for safe climbing?

If your ladder system doesn’t meet OSHA’s updated fall protection requirements, it’s time to make changes.

2. Upgrade to a Compliant Fall Protection System

If your existing ladder only has a safety cage, you’ll need to install:

- A personal fall arrest system (harness, lanyard, and anchor point)

- A ladder safety system (like a rail system or cable system)

OSHA does not require employers to remove existing ladder cages, but they are no longer considered a sufficient safety measure.

3. Train Workers on Proper Fall Protection

Even the best fall protection system won’t work if it’s used incorrectly. Workers should know how to:

- Properly attach to vertical lifelines and rail systems

- Use self-retracting lifelines for better mobility

- Inspect ladder safety devices before each climb

- Follow OSHA’s walking-working surface requirements

Why Malta Dynamics is Your Partner in Fall Protection

Keeping workers safe when working at heights isn’t just about following OSHA’s ladder requirements—it’s about making sure every worker gets home safely at the end of the day. If your job site still relies on ladder cages as a primary safety measure, now is the time to upgrade to a fall arrest system or ladder safety system that meets OSHA standards.

At Malta Dynamics, we provide fall protection systems that meet the latest OSHA regulations and fit a variety of ladder safety needs. Whether you need a vertical lifeline, a self-retracting lifeline, or a full ladder safety system, we have the right equipment to keep your workers safe.

How We Can Help:

- OSHA-Compliant Ladder Safety Systems – We offer rail systems, cable systems, and anchor points to keep workers protected.

- Personal Fall Arrest Solutions – Harnesses, fall arrest systems, and lifelines designed for fixed ladders over 24 feet.

- Expert Guidance on Upgrading Your Ladder Systems – We help businesses move away from caged ladders and meet OSHA compliance before the final deadline.

Make the Switch to Safer Ladder Systems Today

The revised ruling means ladder cages are no longer enough. By upgrading to a modern fall protection system, you’re keeping your team safer and avoiding compliance issues down the road.

Don’t wait until the final deadline—start upgrading your ladder safety today. Contact Malta Dynamics to find the right fall protection system for your job site.