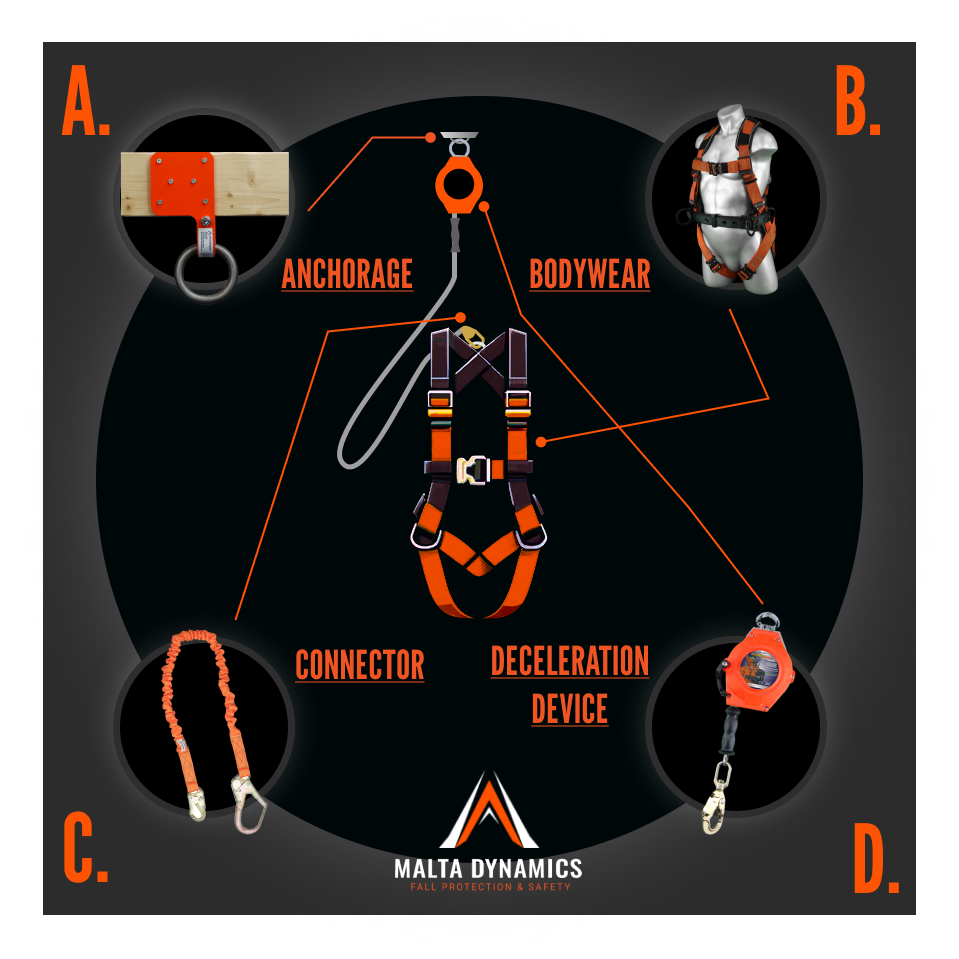

Your anchor can be as simple as a cross arm strap wrapped around a steel beam, or it can be an engineered solution specific to your hazard that is unlike any anchor anywhere else. Regardless of how simple or complex your anchorage, it must provide the same protection. Detailed in the Occupational Safety and Health Administration (OSHA) 1915.159(a)(9) “anchorages shall be capable of supporting at least 5,000 pounds (22.24 Kn) per employee attached, or shall be designed, installed, and used as follows:

- 159(a)(9)(i) As part of a complete personal fall arrest system which maintains a safety factor of at least two; and

- 159(a)(9)(ii) Under the direction and supervision of a qualified person.”

Your bodywear will be a full body harness (body belts became unacceptable January 1, 1998). Be sure to choose your body harness for your specific job, environment, and that you have the correct size and it is adjusted to your body before working at heights.

The connector(s) have this criteria according to OSHA 1915.159(a)(1), “Connectors shall be made of drop forged, pressed, or formed steel or shall be made of materials with equivalent strength.

- 159(a)(2) Connectors shall have a corrosion-resistant finish, and all surfaces and edges shall be smooth to prevent damage to the interfacing parts of the system.

- 159(a)(3) D-rings and snaphooks shall be capable of sustaining a minimum tensile load of 5,000 pounds (22.24 Kn).

- 159(a)(4) D-rings and snaphooks shall be proof-tested to a minimum tensile load of 3,600 pounds (16 Kn) without cracking, breaking, or being permanently deformed.

- 159(a)(5) Snaphooks shall be sized to be compatible with the member to which they are connected to prevent unintentional disengagement of the snaphook caused by depression of the snaphook keeper by the connected member, or shall be of a locking type that is designed and used to prevent disengagement of the snap-hook by contact of the snaphook keeper by the connected member.

- 159(a)(6) Snaphooks, unless of a locking type designed and used to prevent disengagement from the following connections, shall not be engaged:

- 159(a)(6)(i) Directly to webbing, rope or wire rope;

- 159(a)(6)(ii) To each other;

- 159(a)(6)(iii) To a D-ring to which another snaphook or other connector is attached”

Your PFAS will have several connectors including; D rings, snaphooks, carabiners and lifeline connection points.

The deceleration device is the piece of fall protection equipment that arrests fall forces to a level tolerable by the human body. Whether it is a single leg lanyard with a sewn shock pack or the latest self-retracting lifeline with patented technology, the deceleration device is required by OSHA to “limit the maximum arresting force on a falling employee to 1,800 pounds (8 Kn) when used with a body harness; 1915.159(b)(6)(ii)

- 159(b)(6)(iii) Bring a falling employee to a complete stop and limit the maximum deceleration distance an employee travels to 3.5 feet (1.07 m), and

- 159(b)(6)(iv) Have sufficient strength to withstand twice the potential impact energy of an employee free falling a distance of 6 feet (1.83 m), or the free fall distance permitted by the system, whichever is less”

All of these components make up the Personal Fall Arrest System. The components of the system must also work together to achieve OSHA standard 1915.159(b)(7), “Personal fall arrest systems shall be rigged such that an employee can neither free fall more than 6 feet (1.83 m) nor contact any lower level”.

When determining the free fall distance for an employee to avoid contact with a lower level, your fall hazards may require use of lifelines and other components that limit free fall distance. This is normally achieved by utilizing a self-retracting lifeline that is rated for shorter stopping distances by the manufacturer.

A PFAS is only effective for a well trained employee with up to date inspections. OSHA standard 1915.159(c)(5) states, “Personal fall arrest systems shall be inspected prior to each use for mildew, wear, damage, and other deterioration. Defective components shall be removed from service.” Standard 1915.159(d) explains, “Training. Before using personal fall arrest equipment, each affected employee shall be trained to understand the application limits of the equipment and proper hook-up, anchoring, and tie-off techniques. Affected employees shall also be trained so that they can demonstrate the proper use, inspection, and storage of their equipment.”