Fast FREE Shipping & FREE Returns.Fast FREE Shipping & FREE Returns.Same Day Shipping if Order Placed by 2pm EST!Fast FREE Shipping & FREE Returns.Same Day Shipping if Order Placed by 2pm EST!Fast FREE Shipping & FREE Returns.Same Day Shipping if Order Placed by 2pm EST!

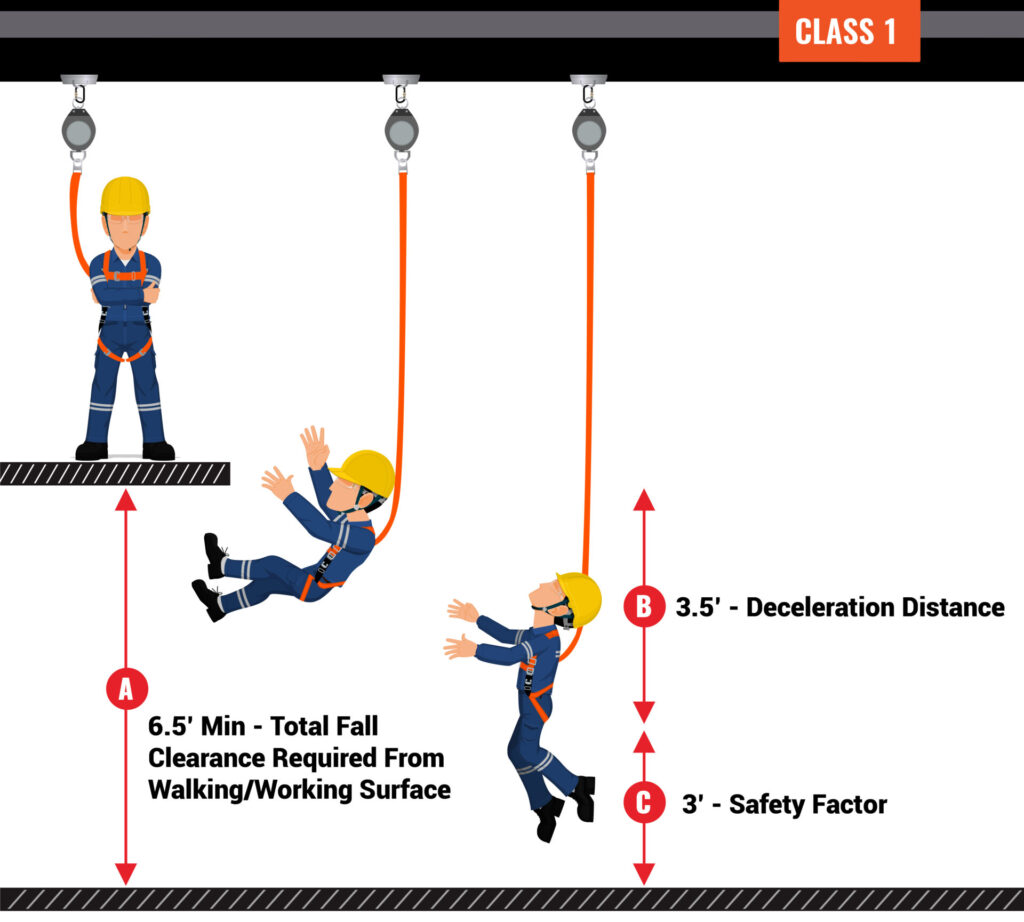

- Anchors

- Harnesses

- Lanyards & Connectors

- SRL's

- Confined Space

- PPE

- Kits

- Mobile Fall Protection

- Rentals

- Hunting Safety

-

Malta Hunting Products

Tree stand safety you can trust and wear all day.

We’ve taken our expertise in Fall Protection and applied it to our passion for hunting. The Malta Hunting Safety line represents the most premium and comfortable tree stand products on the market.

check out our youth ultralight harness kit

-