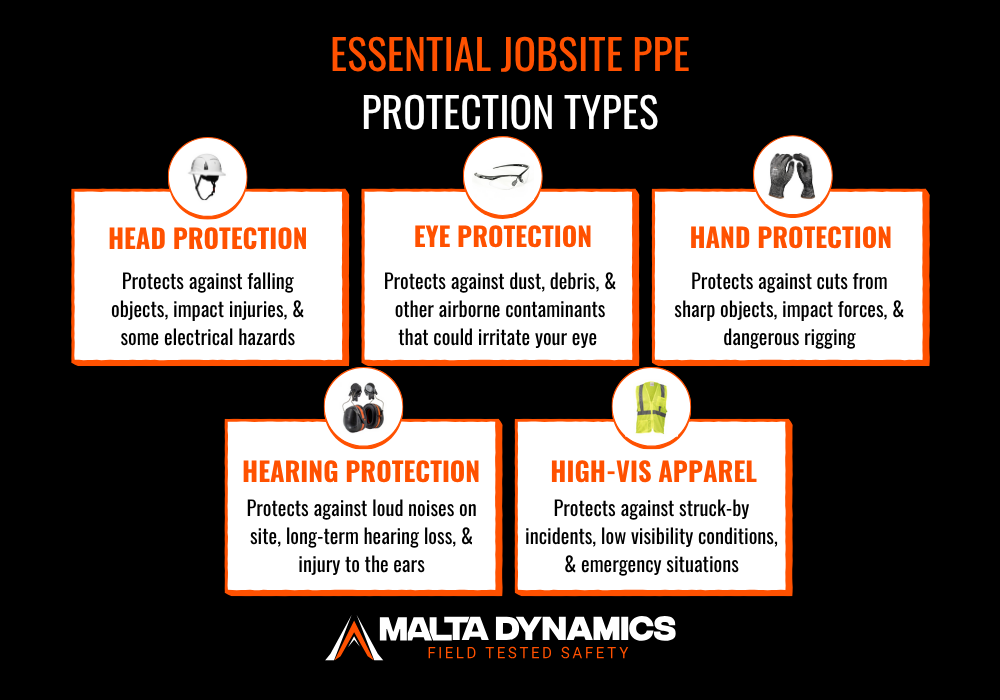

The Short Answer: Fall protection PPE is essential for keeping workers safe at height. By combining helmets, eyewear, gloves, hearing protection, and high-visibility gear with fall protection equipment like harnesses and connecting devices, workers can securely complete their work. A complete fall protection program ensures that crews are protected from fall hazards, compliant with OSHA and ANSI standards, and confident on every jobsite.

Falls remain the leading cause of serious injuries and fatalities in the construction industry and general industry alike. While a safety harness, self-retracting lifelines, and anchors are critical components of a complete fall arrest system, workers also need the right personal protective equipment to stay safe. PPE forms the first line of defense—protecting against falling objects, struck-by hazards, noise, and other risks present at height.

In this guide, we’ll break down the fall protection equipment and related safety supplies every crew should include in their fall protection program.

Head Protection

Protecting the head is one of the most important elements of any fall protection system. A strong hazard assessment will always flag risks from falling objects, bumping into beams, or even accidental contact with hazardous material. Hard hats and helmets serve as a core piece of protective equipment, helping to keep workers safe from impact injuries.

OSHA requires helmets whenever there is a fall hazard or potential head injury, and the American National Standards Institute (ANSI Z) provides testing requirements for impact and electrical resistance.

Hard Hats

Hard hats remain a staple of occupational safety. Their suspension systems distribute impact forces to reduce injury risk.

- Cap Style: Popular for general industry tasks and aerial lift work thanks to improved visibility.

- Full Brim: Delivers all-around protection from sun, rain, and debris, making it especially useful in outdoor work areas.

APEX Type 2 Full Brim Safety Helmets

Designed for top, front, back, and side impact, these helmets are essential in environments with multiple hazards, including scaffolding, steel erection, and confined space work. Available in Class E (electrical protection up to 20,000 volts) and Class C (ventilated, non-electrical), they address both environmental and electrical challenges.

APEX Type 2 Safety Helmets

Climbing-style helmets with chin straps help keep helmets secure during a free fall or sudden movement. They integrate with other safety equipment such as earmuffs and face shields, ensuring comprehensive protection for at-height workers.

APEX Type 1 Safety Helmets

Providing impact resistance only at the top of the head, Type 1 helmets are reliable for jobs where hazards come primarily from overhead. Like Type 2, they include chin straps and slots for add-on personal protective equipment.

Eye Protection

Eye protection is a non-negotiable element of workplace safety. Dust, sparks, and splinters are common in the construction industry, and OSHA mandates protection equipment whenever these hazards are present. ANSI Z87.1 governs impact resistance and durability standards.

- Safety Glasses: Lightweight, fog-resistant, and practical for everyday work areas.

- Safety Goggles: Provide a sealed fit to protect against fine particles, chemicals, or sparks.

Hand Protection

Hands face constant risk from tools, rigging, and sharp materials. OSHA requires employers to supply gloves as personal protective equipment whenever exposure exists.

- Work Gloves: Reinforced palms improve grip and comfort across many applications.

- Performance Gloves: Built for impact resistance, abrasion, and vibration control, offering added protection for high-wear jobs.

Hearing Protection

Jobsites with heavy machinery and safety equipment often exceed OSHA’s permissible noise levels. Long-term exposure without protection equipment can lead to permanent hearing loss.

- Earplugs: Lightweight and effective for extended use.

- Helmet-Mounted Earmuffs: Compatible with fall harnesses and helmets for integrated safety.

High-Visibility Apparel

Struck-by incidents remain a top fall hazard on jobsites. High-visibility apparel improves fall prevention by making workers easier to see in low-light conditions or near moving equipment.

- Hi-Vis Vests: Easy to layer over clothing and available in multiple ANSI classes.

- Hi-Vis Shirts: Keep workers visible without requiring layering—ideal in hot environments.

Additional PPE Considerations

Respiratory Protection

When working in dusty, fume-filled, or chemical-heavy work areas, respiratory protection becomes a critical part of a fall protection program. Proper respirators and masks help keep workers safe from inhaling hazardous material that can compromise health and reduce focus at height. Selecting the right equipment depends on the environment and the type of contaminants present.

Footwear

Slip-resistant and puncture-resistant footwear provides essential stability for at-height workers. Proper boots reduce the chance of falls into a lower level while also protecting against sharp objects or debris on the ground. Reliable footwear is a foundational piece of personal protective equipment for both construction industry and general industry environments.

Specialty PPE

Certain jobs demand more than standard safety equipment, especially in extreme or hazardous conditions. Harness-compatible cold weather clothing, rain gear, or flame-resistant apparel allow workers to maintain protection while adapting to environmental challenges. Specialty PPE ensures that protection systems stay effective regardless of weather, task, or exposure to hazardous material.

All personal fall protection and protection systems must be inspected by a competent person. Damaged or expired equipment cannot provide reliable fall restraint or fall arrest capabilities.

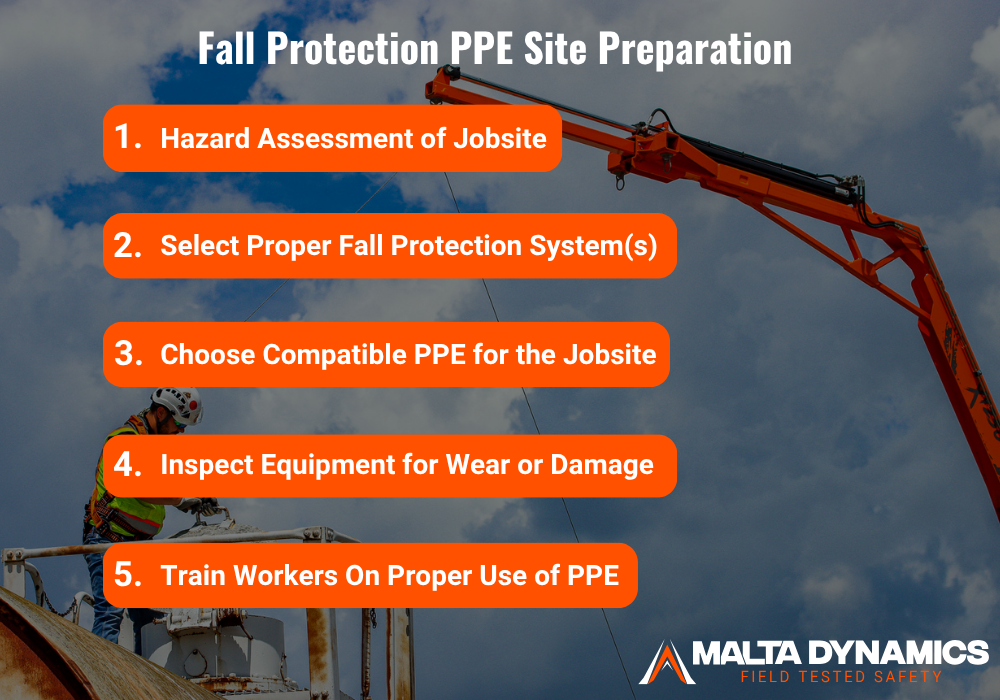

Proper Jobsite Fall Protection Program

A well-structured fall protection program helps safety managers and crews approach workplace safety at height with clarity. Following a clear flow ensures the right equipment, training, and systems are in place:

Step 1: Hazard Assessment

Identify fall hazards across the work area, including trigger height, confined spaces, aerial lifts, and open tanks. This assessment determines which protective equipment and systems are required.

Step 2: Select the Proper Fall Protection System

Choose between fall arrest, fall restraint, or fall prevention methods depending on the jobsite. A fall arrest system stops a worker after a fall, while restraint systems and prevention methods keep workers from reaching the edge in the first place.

Step 3: Choose Compatible PPE

Match body harnesses, connecting devices, and fall protection equipment to the hazards identified. Personal protective equipment must integrate smoothly with the larger protection system.

Step 4: Inspect Equipment for Wear or Damage

A competent person should carefully inspect all personal fall protection systems before use. Harnesses, self-retracting lifelines, and connecting devices must be free of cuts, frays, cracks, or corrosion to provide reliable protection.

Step 5: Train Workers on Proper Use of PPE

Even the best fall protection equipment cannot keep workers safe without proper training. Crews should learn how to wear a safety harness correctly, connect to anchor points, and use fall restraint or fall arrest systems in compliance with OSHA and ANSI requirements.

Final Thoughts on Fall Protection PPE

Every fall protection system depends on both active controls, like body harnesses and connecting devices, as well as the broader personal protective equipment that keeps crews safe from secondary risks. From helmets and eyewear to gloves, hearing protection, and hi-vis apparel, PPE ensures that at-height workers can do their jobs safely.

Employers who invest in high-quality fall protection equipment, backed by a strong fall protection program, not only protect their crews but also demonstrate a lasting commitment to workplace safety.

Why Choose Malta Dynamics

At Malta Dynamics, we know that the right protection system makes all the difference in the construction industry and general industry. That’s why our line of fall protection equipment—including safety harnesses, self-retracting lifelines, restraint systems, and connecting devices—is designed to keep workers safe at height.

Our gear meets OSHA and ANSI standards, is tested in the field, and is built with input from safety managers and at-height workers who rely on dependable protection every day. Whether you need personal fall arrest systems, fall restraint options, or PPE that integrates seamlessly with your fall protection program, Malta Dynamics delivers safety equipment you can trust.

Protect your crews with confidence. Explore Malta Dynamics’ full range of fall protection systems and personal protective equipment today.